The Sales and Distribution (SD) application component fulfills many of the international requirements that supports the sales and distribution activities with functions such as pricing and conditions, customer order processing, delivery monitoring, billing, credit and risk management.

Document Flow in Sales

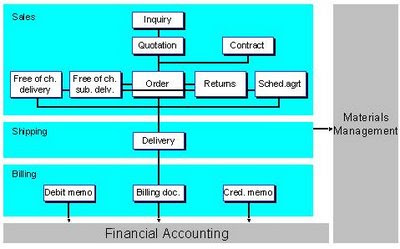

The sales documents you create are individual documents but they can also form part of a chain of inter-related documents. For example, you may record a customer’s telephone inquiry in the system. The customer next requests a quotation, which you then create by referring to the inquiry. The customer later places an order on the basis of the quotation and you create a sales order with reference to the quotation. You ship the goods and bill the customer. After delivery of the goods, the customer claims credit for some damaged goods and you create a free-of-charge delivery with reference to the sales order. The entire chain of documents – the inquiry, the quotation, the sales order, the delivery, the invoice, and the subsequent delivery free of charge – creates a document flow or history. The flow of data from one document into another reduces manual activity and makes problem resolution easier. Inquiry and quotation management in the Sales Information System help you to plan and control your sales.

The following graphic shows how the various types of sales documents are inter-related and how data subsequently flows into shipping and billing documents.

Basic Process of how Packing Works

Let's say you want to pack a material shirt_jai in test_pack.

Using MM01, create material type=packaging test_pack

[SPRO]

IMG-Logistics Execution-Shipping-Packing-

Define Packaging Material Types

Let's say JPAC. The settings that I chose:

Plant determ. - Plant is entered manually in handling unit

Pack. matl. cat. - Packaging materials

Generate Dlv. Items - blank

Number assignment - Number range interval 'HU_VEKP'

IMG-Logistics Execution-Shipping-Packing-

Define material group for packaging material

Let's say JGRP

IMG-Logistics Execution-Shipping-Packing-

Define allowed packaging materials

JGRP - JPAC

MM02: Check settings for the materials

First, test_pack

Sales:General/Plant -> Matl. Grp. Pack. Matls: JGRP (Note)

Sales:General/Plant -> Packaging Mat. Type: JPAC (Note)

Basic Data 1 -> Material: JMAT

Then, shirt_jai

Sales:General/Plant -> Matl. Grp. Pack. Matls: JGRP

Sales:General/Plant -> Packaging Mat. Type: -

Basic Data 1 -> Material: JMAT

VL01N Outbound Delivery -> Packing

Enter the materials at top and at bottom

The "Packing Process" with an Example

Example:

You created a order for a material(R-1160 - hard disks) for a qty - 120 pieces.

You need to create a delivery and

A)pack 40 pieces each of the material are grouped together into larger cardboard boxes (PK-100 - shipping/packing material) and

B)these 3 cardboard boxes are put into pallet (PK-095).

Solution:

A)Packing 40 pieces each of material (40 x 3 = 120 pieces)

1)Goto [VL02N] to change the delivery, you already created.

Or you can do the following steps while you are creating a delivery also.

2)Go to "pack" icon.

3)In the upper section, enter the "packing material" (PK-100)

4)In the lower section, change the "partial quantity" to 40 of material R-1160.

5)Select both the lines of upper section and lower section and click the green ok. It generates a shipping unit/handling unit number.

6)Now, select both lines of upper & lower section & click the button "per part. qty" (New HU per part qty of material)

Check: click "General Overview" icon to see whether it packed 40 pieces of material in 3 cartons.

B)Packing all 3 cartons in one big carton(PK-095)

1) from above screen, click "pack HUs" (pack shipping unit)

2)enter the packaging material (PK-095) in the upper section and select this line.

3)select 3 lines of PK-100 in lower section since you want to pack them in PK-095.

4)selecting both lines, click "pack" icon.

5)Now all the 3 cartons(PK-100 with 40 pieces each of material) are packed in one big carton (PK-095).

Check: "General overview" icon.

No comments:

Post a Comment